ASPION L-Track – FAQ & Support

In the FAQs you will find answers to your questions about the ASPION L-Track multisensor data logger and the ASPION Cloud as well as topics relating to installation and transportation. More detailed instructions can be found in the user manual or summarized in the quick guide. The country list contains a list of regions in which the L-Track has network coverage. Our support team will be happy to help you with any problems. For orders or term extensions, please contact our sales team.

Quick start and preliminary considerations when using the L-Track

To set up the ASPION L-Track, first set up the ASPION Cloud after receiving the order. In a second step, activate the device.

Step 1: Set up in the ASPION Cloud

- Log in to the ASPION Cloud with your login details. You will receive these by email when you place your first order.

- Start the initial setup of the cloud at any time by

- Creating groups and assigning devices

- Activating and configuring shock settings

- Setting alarms and notifications

- When setting up shock settings, alarms and notifications, bear in mind how sensitive your transported goods are.

When setting up shock settings, alarms and notifications, bear in mind how sensitive your transported goods are.

Step 2: Device activation

- Pull off the red "Remove" label to reveal the light sensor.

Note: Make sure that sufficient light falls on the sensor to activate the device. Shine a flashlight on the light sensor in poor lighting conditions. - The initial synchronization of the device with the ASPION Cloud takes a few minutes. A measurement is then taken every hour on the hour and after 8 hours the first data transfer to the ASPION Cloud takes place (even without setup).

- After the first transfer, you can view and analyze the measurement data.

You can find further support for setting up in the quick guide.

Since the goods to be transported are as different as their manufacturers, there is no general formula for determining threshold values and shock duration. For example, a sensitive measuring instrument should be monitored with different thresholds than a pump weighing several tons. It is therefore best to work together with your technical experts to consider the following:

- Which means of transport are used? Overland by truck in Eastern Europe or by ship to overseas with subsequent truck transport of several hundred kilometres over land with unfavourable road conditions?

- Choose a threshold value suitable for the means of transport, e.g. acceleration values of up to 4 g innately occur during manoeuvring when transported by rail.

- Where is my cargo particularly sensitive? This is a good indication of the best place to attach the shock sensor. In any case, you should attach the data logger directly to the object and not to the transport packaging...

Attach the data logger rather in the upper third, because when falling over or falling sideways, the leverage - and thus the acceleration effect - is higher there than, for example, on the pallet at the base of the object. If possible, use screws for fastening, alternatively you can use industrial adhesive tape (e.g. 3M VHB 5952F double-sided high-performance adhesive tape with 19 mm width, own tests with it have shown no damping of the shock values): While short pulses of a few milliseconds have less effect at high acceleration values, longer shocks (e.g. with a duration of more than 50 milliseconds) have a greater effect on the goods to be transported.

- If necessary, ask business partners, e.g. suppliers of components, about possible loads the component is suitable for.

Further general information can be found in our whitepapers: "The Effect of Accelerations" and "Loads during Transport" in the Worth Knowing section.

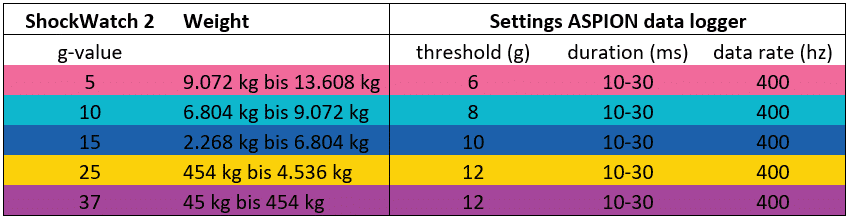

Manual shock indicators like ShockWatch 2 are widespread and simple to use. Just as simple is the informative value, because the indicator turns red as soon as it has been triggered. No further statements can be made about this. Choosing the right indicator depends on the right version. A simple table shows which indicator can be used.

If you have already gained experience with such indicators, we would like to give you a little help here on how to find the right shock detection setting for your ASPION data loggers. This only serves as a guideline. Of course, we will be happy to advise you in detail on the use of ASPION data loggers at any time.

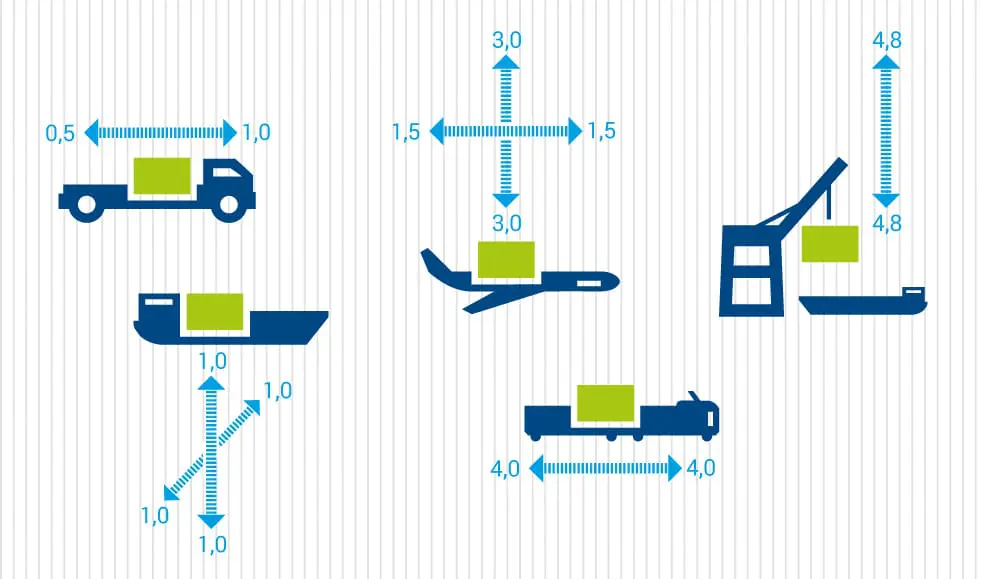

The stress that export goods are exposed to per se when transported by truck, ship or air freight, the acceleration that occurs, for example, when handling containers and how to find the right settings for the use of digital data loggers can be found in the whitepaper "Loads during transport" (Download PDF). This chart gives you an initial overview of accelerations as they occur per se:

Questions about the effect of acceleration on cargo are frequently asked and can only be answered individually. Depending on the transported goods and their sensitivity to shocks and vibrations, they react very differently. In the whitepaper "The Effect of Accelerations" (Download PDF) we have listed examples which should provide you with clues for a better assessment.

Transportation and certifications

Export information:

Goods tariff number ASPION L-Track: 9031 8080

Country of origin Germany (EU).

The ASPION L-Track uses alkaline batteries and is therefore not subject to labeling upon delivery.

The following declarations of conformity and directives are valid for the ASPION L-Track:

- CE / ROHS / REACH / WEEE

- RED (EU)

- FCC (USA)

- IC (Canada)

- WPC (India)

Transportation by air freight is not permitted in active condition. Air freight approval is planned.

ASPION Cloud

Use the smart rule "On measurement explicit threshold create alarm" to create rules for individual devices according to which alarms are triggered. To do this, select the sensor type and define the threshold values for which an alarm should be generated.

You can set up notifications individually using the smart rules. You choose for which sensor types alarms are triggered from which threshold value. With additional Smart Rules, you can create email notifications for triggered alarms.

You will find step-by-step instructions in the Smart rules and alarms section of the user manual.

The data is transmitted to the ASPION Cloud every 8 hours by default. This transmission interval can be customized in the device configuration.

Additionally, the following settings can be adjusted in the device configuration:

- Measurement interval: Determines how often values such as temperature, humidity, light, barometric pressure, as well as battery capacity and voltage are recorded. The default is once per hour.

- Shock detection: Shock events are recorded event-triggered, independently of the measurement interval. Shock detection is disabled by default.

After device activation, the sensor data is automatically sent to the ASPION Cloud as soon as a mobile connection can be established. Click on the device in the ASPION Cloud to view the data in detail.

Pay attention to the following sources of error to ensure that data is transferred from the ASPION L-Track to the ASPION Cloud:

- Activation procedure: When removing the "Remove" label, make sure that there is enough light on the light sensor to activate the device. In poor lighting conditions, shine a flashlight on the light sensor for a few seconds.

- Packaging: If you use anti-corrosion packaging made of shielding material (e.g. aluminum foil), this creates a Faraday cage, which prevents mobile phone transmission. You can prevent this by excluding a small area, ideally close to the device, from the shielding, for example by installing a viewing/inspection window (e.g. Hermann window). This is the only way to ensure mobile radio transmission when using corrosion protection packaging.

- Mobile phone signal: Please note that no data can be transmitted to the ASPION Cloud without a mobile phone signal. For example, on the high seas or in undeveloped areas, this leads to a delay in data transmission. All measured values are stored on the device until the next possible transmission, so no data is lost.

There are two ways to capture location information with the ASPION L-Track:

- Cell tower location (approximate localization):

- The location of the cell tower is automatically determined during each transmission.

- Accuracy is typically within a few hundred meters.

- In rare cases, the cell tower location may be unknown. As a result, a successful transmission may not always include a location.

- GPS location (precise localization):

- If GPS is enabled in the device configuration, a precise location is determined in addition to the cell tower location.

- GPS tracking occurs at the configured interval and only when the signal strength is sufficient.

- A data transmission may occur without a GPS location being available, for example, due to poor signal quality.

The software was developed in Germany and all server locations are in Germany.

Unless otherwise agreed, you have access to the ASPION L-Track data via the ASPION Cloud for a period of 12 months from device activation. You can activate the device within 3 months of delivery. If you do not activate an ASPION L-Track within this period by removing the "Remove" label, the term will start automatically after the 3 months have expired.

You have the option of extending the term of your devices at any time. To do so, please contact the source from which you purchased the devices (manufacturer or certified ASPION partner). Even after the end of the term, you will see the data transferred up to the end of the term in the ASPION Cloud for a further 3 months. After 3 months, the device is removed from the ASPION Cloud. It is still possible to view the device data via the export function.

With the shock details you can trace the exact course of a shock in all 3 axes on the millisecond level. The shock details contain 19 consecutive values per axis for a shock event. You can use this data to trace on which axes the event has affected and for how long. More detailed information can be found on the Data Logger Analysis webpage.

It is helpful to document the position of the sensor on the transported goods by means of a photo in order to derive meaningful analyses. If you have any questions regarding the interpretation of the data, please contact our support team by e-mail at support@aspion.de.

The extent to which a shock event with the recorded details was detrimental to your goods depends essentially on the duration of the acceleration. Vibrations can also be seen in the details. In the case of very strong events, several events can occur within a few seconds or minutes. The interpretation of the data is very individual and depends on the goods being transported. Here are a few examples:

More detailed information can be found on the Data Logger Analysis webpage.

We are happy to help with the interpretation of the data. Please contact our support at support@aspion.de.

ASPION L-Track multisensor data logger

The ASPION L-Track transmits data to more than 140 countries worldwide. Data is transmitted wirelessly via mobile radio using LTE-M and 2G (GSM) as a fallback. Further details on country coverage can be found in this overview.

The ASPION L-Track logs the following sensor values and sends them to the ASPION Cloud in real time via mobile radio:

- Vibrations/shocks

- Location information via mobile radio and optionally with GPS

- Climate data

- Temperature

- Relative humidity

- Barometric pressure

- Light (opening detection)

- Tilt

- Simple orientation

Measured values are logged interval- and/or event-based with a time stamp and temporarily stored in a buffer memory on the battery-operated device until transmission.

The ASPION L-Track can store measurement data securely even without an internet connection so that no data is lost.

The storage capacity varies and can be up to twice as high. The current minimum is:

- 2,000 measurement series (each consisting of temperature, humidity, pressure, light, battery voltage and capacity)

- 450 shocks (including detailed shock information)

- 4,000 tilt measurements

Examples of storage duration:

- Measurement interval 1 hour, shock detection inactive -> approx. 12 weeks

- Measurement interval 1 hour, 100 shocks -> approx. 9 weeks

- Measurement interval 1 hour, 100 shocks, 1,000 inclination measurements -> approx. 6 weeks

- Measurement interval 15 minutes, shock detection inactive -> approx. 3 weeks

- Measurement interval 15 minutes, 100 shocks -> approx. 2.5 weeks

- Measurement interval 15 minutes, 100 shocks, 1,000 inclination measurements -> approx. 12 days

Note: The storage capacity of new devices will soon be increased by a factor of 20. Devices already delivered will support a minimum storage capacity twice as high in future.

The ASPION L-Track uses four alkaline AA 1.5V batteries, which can be changed by the user. Lithium AA 1.5V batteries can also be used for longer operating times. In this case, the applicable regulations in accordance with the dangerous goods directives must be observed.

Proceed as follows to change the batteries:

- Open the housing by unscrewing the screws on the top of the housing with a Torx T10 screwdriver.

- Remove the batteries with a blunt non-metallic object (e.g. plastic ball

(e.g. plastic ballpoint pen) from the holder. Avoid contact with the electronics. - Wait at least two minutes and insert four new AA 1.5V batteries (alkaline or lithium) into the holders. Observe the correct polarity.

- Tighten the housing with a maximum tightening torque of 0.5 Nm. Improper handling will invalidate the warranty; the housing may also leak and water ingress may destroy the device.

Note: When changing the battery, please note that the device requires up to one hour before measured values are saved again. Historical measured values are transmitted with the next data transfer and are retained in any case.

The ASPION L-Track has a non-volatile memory in which the recorded data is stored permanently. Even after the last data transfer, the ASPION L-Track continues to record data for several days as long as the battery voltage is sufficient.

Depending on the configuration, the ASPION L-Track can be used autonomously for several years with one set of batteries.

When delivered, the ASPION L-Track is in energy-saving mode and consumes little power. When using alkaline batteries, the ASPION L-Track requires around a third of the battery capacity per year with standard settings. Frequent data transmission, GPS and shock detection reduce the battery life. The runtime can be approximately doubled by using lithium batteries (hazardous goods guidelines must be observed). The data may vary depending on the climatic conditions.

As a general rule, attach the data logger directly to the transported goods. It is best to select a location where your transported goods are most sensitive to impacts.

Recommended mounting

- on steel: M4 ISO 7380 FL

- on wood / sheet metal: flat-head screws max. 3.9 mm thread diameter (e.g. DIN 7981)

- Tightening torque 0.4 - 0.5 Nm

If screw fastening is not possible or desired, the following alternatives are available:

- Industrial adhesive tape, e.g. from 3M (recommended: 3M 5925F)

- Cable ties

- Magnets (optionally available with mounted magnets)

Please note the suitability for a firm connection of the data logger to your transported goods.

Packaging and possible restrictions on mobile radio transmission

- To record temperature and humidity, make sure that the white membrane on the top of the device is not covered when packing the device. If lux values are to be recorded via the light sensor, keep the adjacent light sensor uncovered.

- If you use anti-corrosion packaging made of shielding material (e.g. aluminum foil), this creates a Faraday cage, which prevents mobile phone transmission. You can prevent this by excluding a small area, ideally close to the device, from the shielding, for example by installing a viewing/inspection window (e.g. Hermann window). This is the only way to ensure mobile radio transmission when using corrosion protection packaging.

As the relative humidity is subject to very large deviations due to temperature fluctuations (e.g. day temperature 20° C, night temperature 8° C), the threshold values for alarms and notifications must be selected accordingly using the Smart Rules for relative humidity. Our recommendations:

- If the goods are packed in corrosion-proof packaging with appropriate film and desiccant, set the threshold value for relative humidity to 40 %. Corrosion can already occur at a relative humidity of > 40 %.

- If the goods are not susceptible to corrosion, you do not need Smart Rules for humidity. An hourly interval recording of the relative humidity continues to take place regardless of this.

Documents about the L-Track

Instructions & description

Support

If you have any questions or problems, our support team will be happy to help you:

Phone: +49 721 85149-128

support@aspion.de